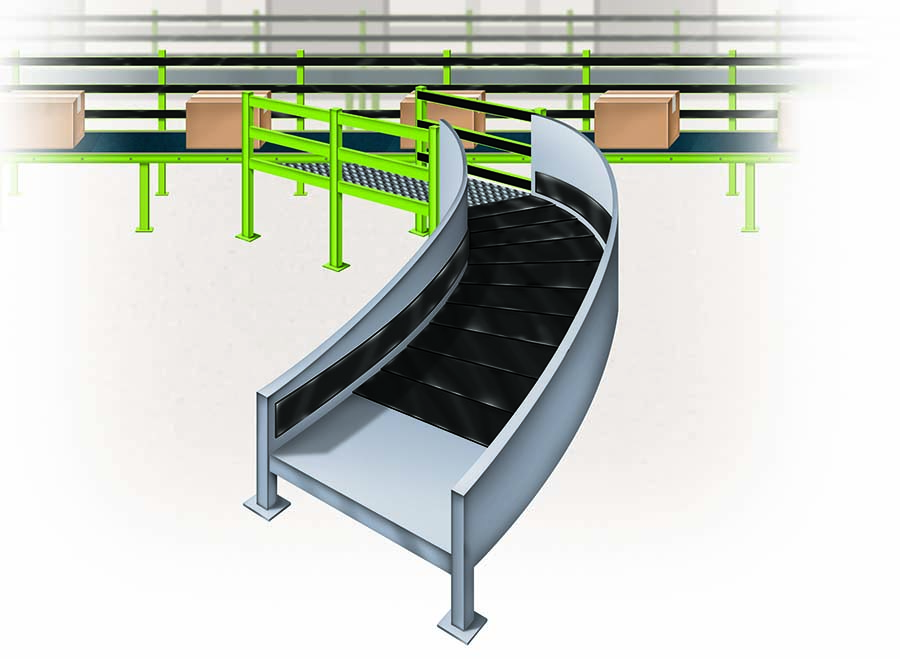

DuraSurf™ Product Overview

Crown Plastics’ line of DuraSurf™ UHMW-PE products are manufactured in continuous sheets and variable thicknesses, making them the perfect solution for a wide variety of material handling applications. And with the introduction of DuraSurf™ STS (Silicon Treated Surface), Crown was able to increase package flow in conveyance systems.

The incredible durability and versatility of DuraSurf™ UHMW-PE makes it a favorite among engineers and designers in nearly every industry worldwide. UHMW-PE’s long molecular chain gives it a host of exceptional attributes:

high abrasion resistance, low coefficient of friction and unparalleled impact resistance, even in cryogenic environments.